Quartz Worktops

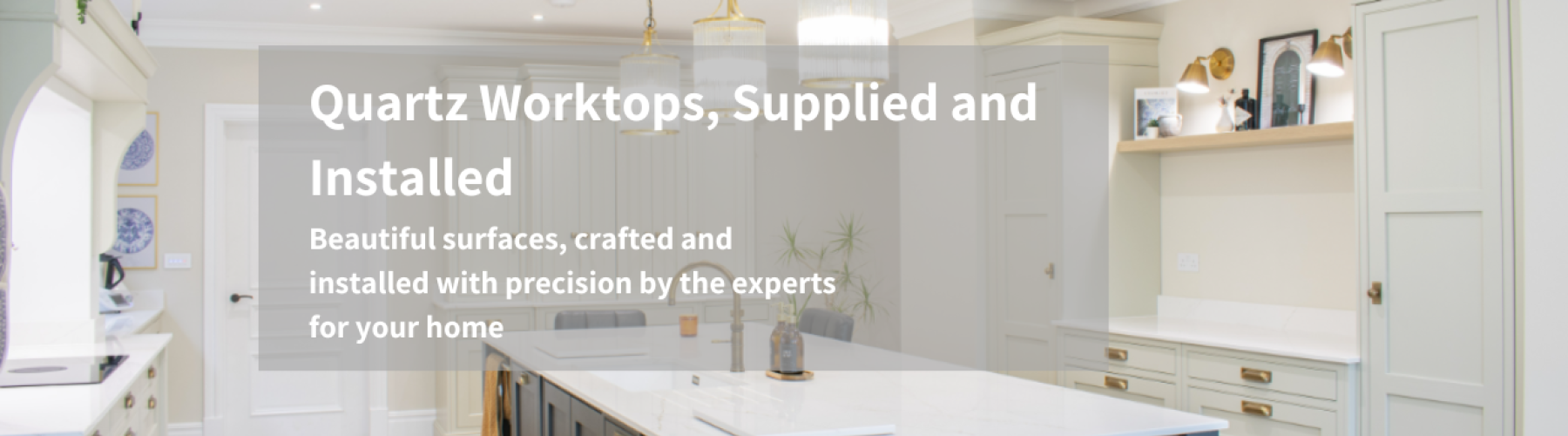

Bespoke Quartz Worktops, Supplied and Installed

What are Quartz Worktops?

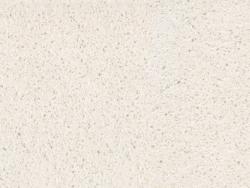

Quartz worktops have become the most popular choice for kitchen renovations, making up 80% of our sales. This is mainly due to this material being guaranteed not to stain by most manufacturers and being heat, chip, and scratch resistant. There is now a huge selection of colours, patterns, designs, finishes and thicknesses.

This page provides all the information you need on our quartz surfaces for kitchens and bathrooms and is the perfect guide to this exquisite engineered material.

Quartz Manufacturers

Quartz Worktops Collection

Benefits of Quartz Worktops

Impact resistant

Non-porus

Scratch resistant

Hygienic

High flexural strength

Frost resistant

Heat resistant

Easy to care for

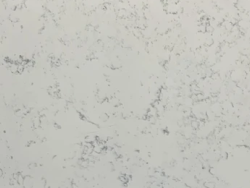

Design Options for Quartz Worktops

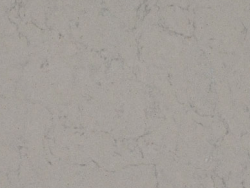

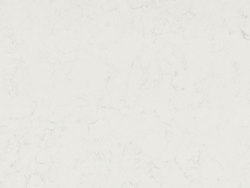

Popular Colour Schemes:

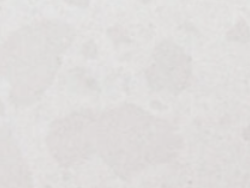

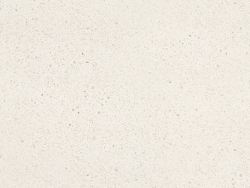

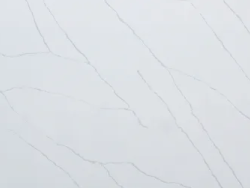

White and Cream: Gives a bright, airy feel

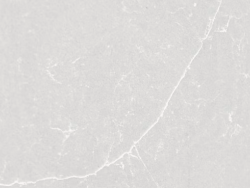

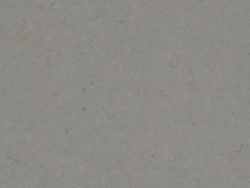

Grey: Light silver to charcoal, grey quartz can compliment a wide range of design styles

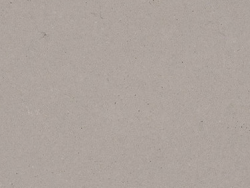

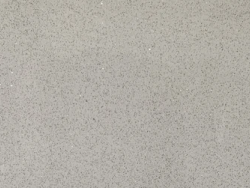

Earth Tones: Beiges, browns, and taupes offer warmth and a natural feel

Bold Colours: For those looking to make a statement, options like red, blue or green are available

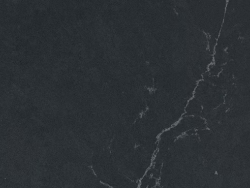

Black: Sleek and sophisticated, black quartz worktops can create a dramatic focal point

Textures & Finishes:

The texture and finish of quartz worktops can significantly impact their appearance and feel. Common options include:

Polished: A glossy, reflective finish that enhances colour-depth and creates a luxurious look

Honed: A matte finish that offers a softer, more understated appearance. It's less reflective than polished and can hide fingerprints and water spots in lighter quartz

Leather: This finish provides a subtle texture that resembles the feel of leather to the touch. It's less shiny than polished but has more depth than a honed finish

Suede: Similar to a honed finish but even softer

Textured: Some manufacturers offer textured finishes that provide unique finishes, such as rippled or brushed surfaces

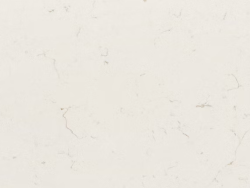

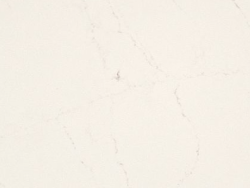

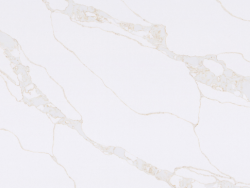

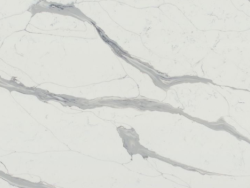

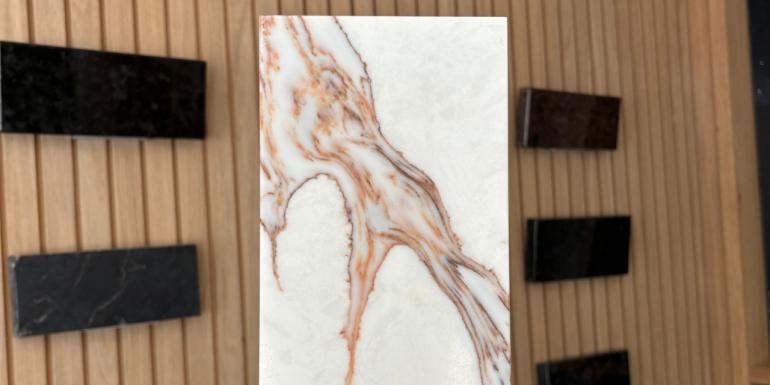

The wide range of quartz designs allows it to look much more natural than it once did, making it difficult to tell if a worktop is quartz or the real thing. These properties make quartz the first choice for developers looking to give warranties on newly built properties as well as home-owners and designers.

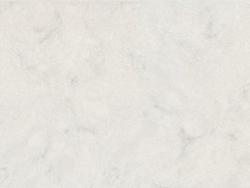

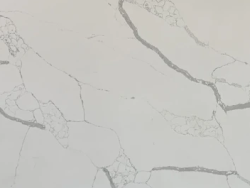

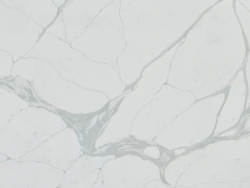

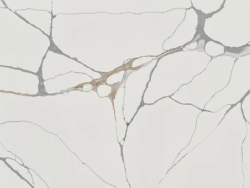

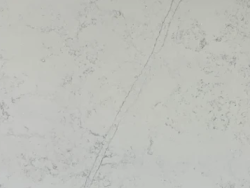

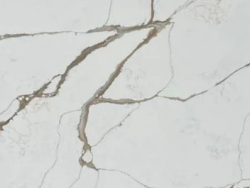

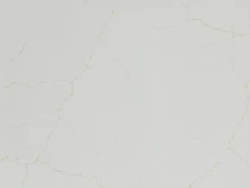

See this image of a printed quartz made to resemble Calacatta Bourgini:

How is Quartz Made?

Quartz worktops are engineered stone surfaces composed of approximately 90-95% ground natural quartz crystals combined with 5-10% polymer resins and pigments. This unique composition results in a non-porous, durable material that offers the best of both worlds: the strength and beauty of natural stone with the consistency and customisation possibilities of engineered materials.

Natural quartz is mined from quarries around the world, the mined quartz is crushed into small particles and refined to remove impurities. The refined quartz particles are mixed with resins, pigments, and occasionally recycled materials like glass or metallic flakes, the mixture is then poured into moulds and subjected to intense vibration to remove air bubbles.

Slabs are cured under high heat and pressure, which solidifies the resin and creates a dense, non-porous surface, the cured slabs are polished or textured to achieve the desired finish. This carefully controlled manufacturing process ensures consistency in colour, pattern, and quality across batches, something that natural stone cannot guarantee.

The industry standard manufacturing lines are made by Breton: https://breton.it/products/plants/bretonstone-silica-free-slab-production-plant

See our detailed guide about how quartz is manufactured here

Quartz vs. Natural Stone

While quartz worktops are often compared to natural stone options like granite or marble, there are several key differences:

Consistency: As quartz is a man-made product, it is more consistent in colouring and pattern compared to natural stone, which can vary significantly from slab to slab. There can be slight differences in batches, so when ordering slabs that join, we ensure that they are from the same batch

Porosity: Quartz is non-porous and guarantees not to stain, unlike natural stone which requires regular sealing

Durability: Quartz and natural stone are very durable but quartz tends to be more resistant to chipping and cracking and has much more flexural strength making it more suitable for bridging and larger overhangs

Maintenance: Quartz requires less maintenance than natural stone and is easier to clean

How Are Quartz Worktops Templated?

Templating is crucial to our worktop process, allowing us to measure and calculate the exact measurements we require, to ensure your quartz worktop fits flawlessly with the rest of your space.

We template worktops using a laser; this maps out the cabinets extremely accurately, a PDF is then supplied to the customer for approval and DXF files are created ready to input into our CNC machines.

How Are Quartz Worktops Fabricated?

The slabs are thoroughly checked before being loaded by forklift onto one of our saws with tilting tables.

DXF files are uploaded from the laser template and nested onto the slab, the saw then cuts out the worktops to the exact sizes with a 400mm water-cooled diamond blade. The primary saws can also cut the unpolished cutouts and large radius curves.

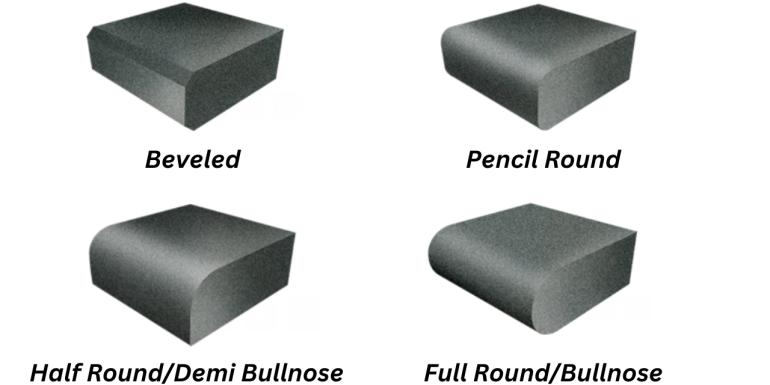

The worktops are then loaded onto the edge polisher using vacuum lifters; this polishes the flat edges and creates a bevel using 5 stages of resin diamond grits and water.

The polished worktops are then loaded onto CNC machines which cut the polished cutouts again using several diamond grinding and polishing heads, allowing for the creation of drainer grooves, and some more detailed polished edges.

Lastly, the tops go to our skilled masons for any hand finishing that is required, and final quality checking.

How Are Quartz Worktops Installed?

- The worktops are carefully placed in position and levelled using plastic packers where required

2. They are then stuck to the cabinets on pads of silicon which prevents movement

3. Next the tops are joined using 2-part-resin and a vacuum join setter which levels the join and pulls it tight, once the glue goes off, it is bladed flat and polished

4. Now upstands are cut to size and silicone to the wall, and sinks are silicon to create a watertight seal. The worktops and kitchen are then given a final clean.

How Do I Care for Quartz?

Whilst quartz is chip, scratch and heat resistant, we recommend using trivets and chopping boards as people generally prepare food in one area, and over the years chopping and prepping will dull most materials. Clean spills ASAP especially for substances like wine, coffee, or turmeric and make an effort not to leave water sitting around the tap and sink area, as limescale is likely to build up.

Avoid using strong alkaline or acidic cleaners and be especially careful with oven cleaner as this will corrode the worktop; if this happens it isn't generally repairable.

For daily cleaning, we recommend soapy water to clean and an e-cloth to buff. For sunburn stains, we recommend spot cleaning with a magic sponge. We provide a cleaning kit with all our installations with everything you need.

- Use a soft cloth or sponge with warm water and mild dish soap

- Avoid harsh or abrasive cleaners, as these can dull the surface over time

- For stubborn spots, use a non-abrasive cleaner specifically designed for quartz surfaces

- Always rinse thoroughly with clean water and dry with a soft cloth to prevent water spots

How Much Do Quartz Worktops Cost?

The cost of quartz worktops can vary but there is generally an option for most budgets. There are multiple factors to consider when calculating how much it will cost:

Brand/Quality

Colour/Pattern

Fabrication Options

Design Complexity

Square meterage required

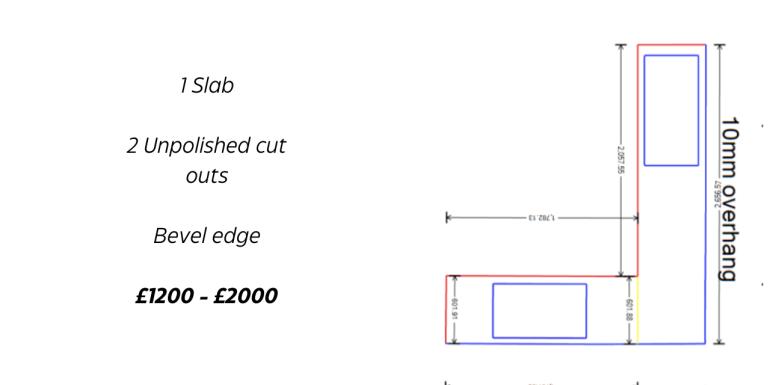

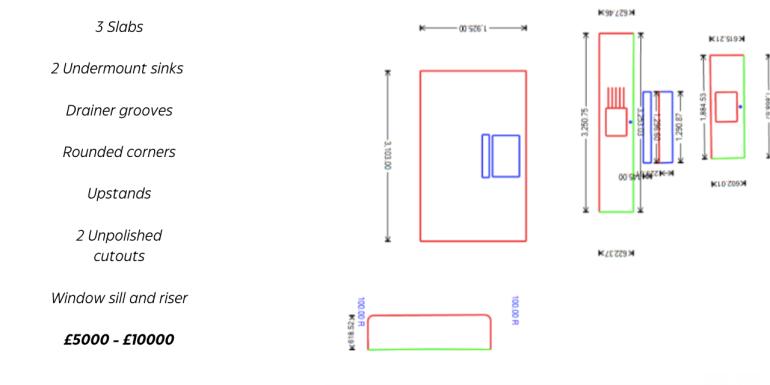

See some real price comparisons here:

Low Price:

Medium Price:

High Price:

How Do I Get a Quote?

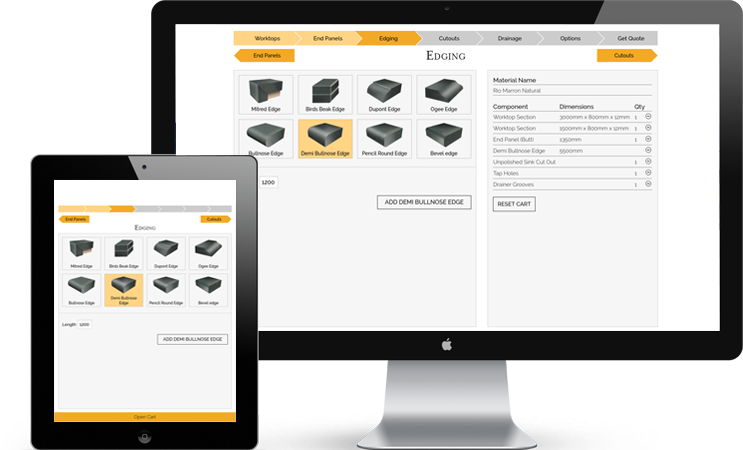

You can visit in person with a plan, send an email, request a site visit, or email a kitchen plan to us. You can also get a price in a couple of minutes using our free worktop pricing tool

Do You Have a Showroom?

Yes, we have a showroom with 100's of samples, and lots of full slabs in our yard. It is well worth visiting to see our full range of materials; if possible, bring samples of kitchen door paint, flooring, wall colours, textiles, etc. so you can put these together with the samples to get the design just right.

Customers often find it useful to bring door, flooring and other samples to find the perfect worktop for their interior scheme.

Replacement Quartz Worktops

Before - Baltic Brown Granite

After - Bloomstone Lincoln Quartz

Thinking about refreshing your kitchen without the hassle or added expense of renovating your entire space? At Henderstone, we offer replacement worktop services for customers throughout Kent; we will remove your old surface, and replace it with a new bespoke-cut stone worktop. Fresh worktops can make a world of difference and are guaranteed to give your kitchen a new lease of life.

For all the information you need on our replacement worktops, see our blog post here

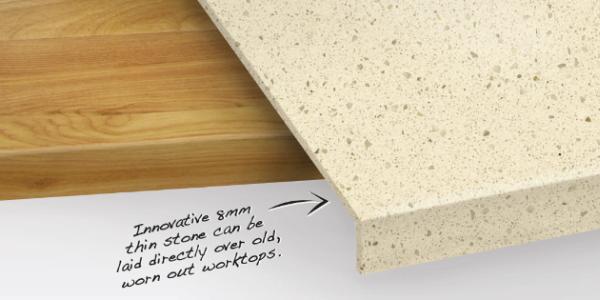

Do You Supply Quartz Overlays?

Yes, we have a range of quartz slabs that are 8mm thick which we use to cover existing worktops. There are restrictions with overlays so where possible we recommend removing and replacing your worktops; contrary to popular belief this costs around the same price.

Should I Be Worried About Silica?

Homeowners should not be worried about silica. It is only harmful when the material is dry-grinded and creates dust; once installed in your home, there is no risk. As a company, we only wet cut in our factory, use water walls for extraction to clean the air, and employees always wear dust masks and powered respirators. All this ensures we meet the highest standards of health and safety requirements.

Most stone manufacturers are also now using minimal silica in their compounds such as Silestone Hybriq: https://www.cosentino.com/en-gb/silestone/hybriq-technology-pro/

Comparing Quartz Manufacturers

When deciding what material you are going to use for your quartz worktops, it is important to first consider the differences between the vast array of quartz manufacturers that we work with. They each have their pros and cons, and some will work better for some people than others, so you must research into what the manufacturer is offering before finalising your decision. Some of the factors to consider are:

Price: One of the most important factors when embarking on any design project, is the price of the product you are looking to purchase. We have our independent pricing on our services such as templating, fabrication, and installation, but it is also a good idea to look into the price of the stone itself, to weigh up the entire cost of the project. Some manufacturers will be more costly than others, with the more premium brands looking at a much higher budget. Evaluate what is suitable for you and make a decision accordingly.

Thicknesses: If your desired worktop has more intricate elements, or you prefer a thinner profile for your worktops, it might be worth looking into the thicknesses that each manufacturer offers. For the most part, 20 & 30mm are standard, however, some of the bigger brands do offer thinner profiles such as 8 & 12mm

Warranty: Different manufacturing brands offer varying warranties as standard, so for your peace of mind, it's crucial to look into these, if anything were to happen to the integrity of the stone itself

Textures: If the finish of your worktop is an important part of your decision, definitely research the different textures that each brand has to offer; from polished and gloss to velvet and suede, there is a stone finish that suits any and every aesthetic preference

Slab Sizes: This is a more intricate part of the decision process, but, particularly if you are on a tighter budget, it may be worth looking at the slab sizes that manufacturers provide. Depending on the amount of sq. meterage you require for your worktop, we may need to order more than one slab, inevitably increasing the price; if a company offers a larger slab size for the material you are after, it is definitely a factor to consider

Here is a short summary of our main quartz suppliers and the key information you need to know:

| Company USP | Price | Thicknesses | Sink Available? | Warranty | Country of Origin | Textures | Slab Sizes | Key Benefits | |

Caesarstone |

| ££££ | 20mm 30mm | No | 25 Years | Israel | Polished Honed Concrete | 3340x1640mm 3040x1440mm |

|

Cambria |

| ££££ | 20mm 30mm | No | Lifetime | USA | High Gloss Matte | 3070x1410mm 3350x1660mm |

|

Cimstone |

| £££ | 20mm 30mm | No | 10 Years | Turkey | Honed Polished Concrete | 3050x1400mm 3100x1520mm 3300x1650mm |

|

Compac |

| £££ | 12mm 20mm 30mm | No | 33 Years | Spain | Polished Glacier Natural | 3300x1630mm 3050x1440mm |

|

Nile Stone |

| ££ | 12mm 20mm 30mm | No | 15 Years | Egypt | Honed Polished Leather Concrete | 3220x1620mm |

|

Silestone |

| ££££ | 12mm 20mm 30mm | Yes | 25 Years | Spain | Matte Polished Suede Volcano | 3250x1590mm 3060x1440mm |

|

Is it Possible to Have a Matching Quartz Sink?

Yes, HOWEVER, Silestone are the only brand that currently make matching sinks. These are only available in some of the range, see full details

This is a mitred Silestone Calacatta Gold integrity sink we installed for a customer.

We are able to build sinks from quartz to match your worktops.

Here is a bespoke double-sink with a sloping drainer that we have previously created for a client

We also supply 1810 sinks which have several finishes on the base and the sides are clad to match your worktop seamlessly

What are the Maximum Quartz Slab Sizes?

Standard slabs: 3000x1400mm

Most manufacturers now supply Jumbo slabs at 3250x1590mm

A few offer Super Jumbo slabs at 3400x1950mm

What Thickness Can I Have for My Worktop?

Standard thicknesses are 12mm, 20mm, and 30mm; however, quartz can be mitred down to create any thickness

Instant Quote

Try our instant quotation tool and get a price right now not tomorrow.